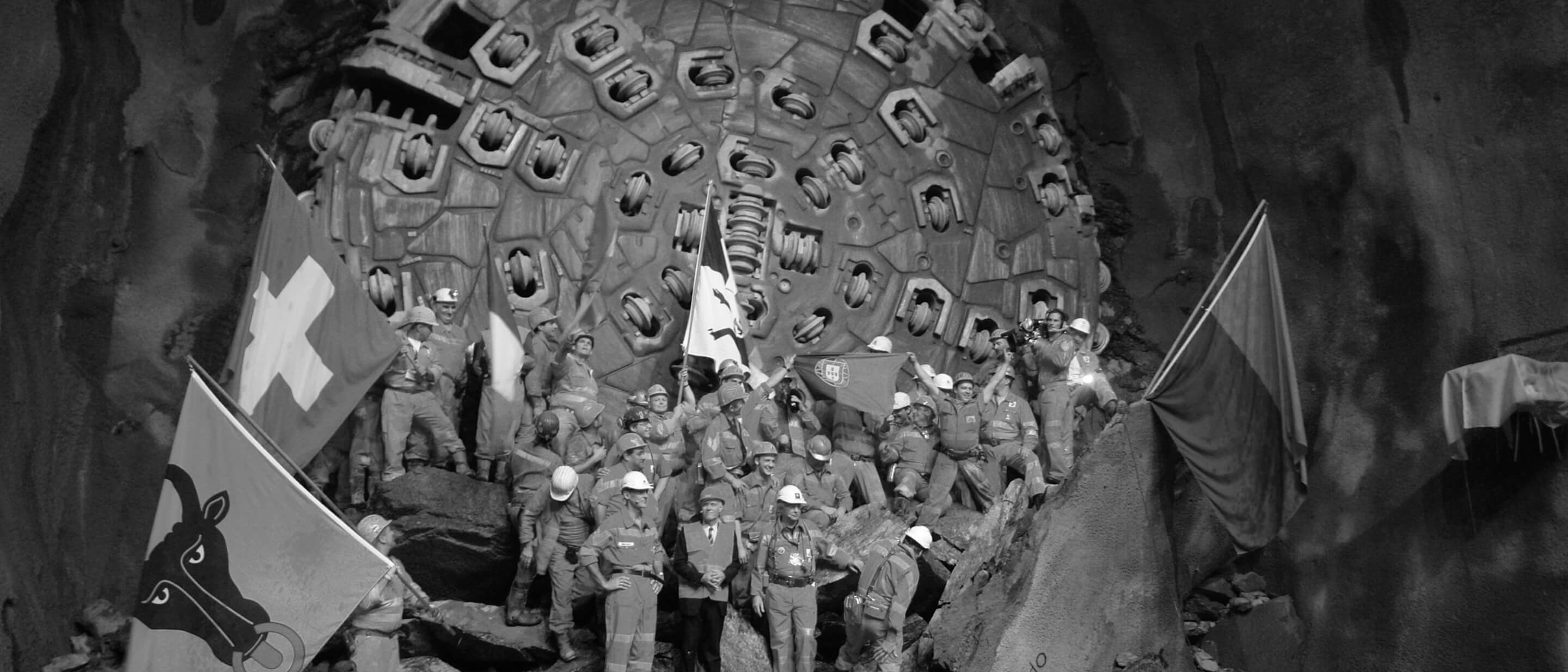

A drilling machine for the Gotthard tunnel

During the construction of the Gotthard Tunnel, “Sissi” ate her way through the rock deep inside the mountain – together with three other giant tunnel boring machines. Sissi’s mighty drill heads weighed 220 tons each, with a diameter of 9.5 meters. Huge pressure cylinders pressed the drill heads against the rock with a pressure of up to 26 tons. The drilling components – each weighing up to 125 kilograms – broke through granite, gneiss and other rock beds layer by layer.

Deep in the tunnel the drop forgings from Buderus Edelstahl played off their first-class quality to particularly impressive effect: Load capacity, wear resistance and weight met the highest requirements. The tunnelling machines were in operation underground for 18 hours per day. Technicians spent six hours maintaining the machines and the drilling tools. Under these enormous loads, our components proved their unique strengths and thus made a decisive contribution to the success of this historic tunneling project.