Testing laboratory

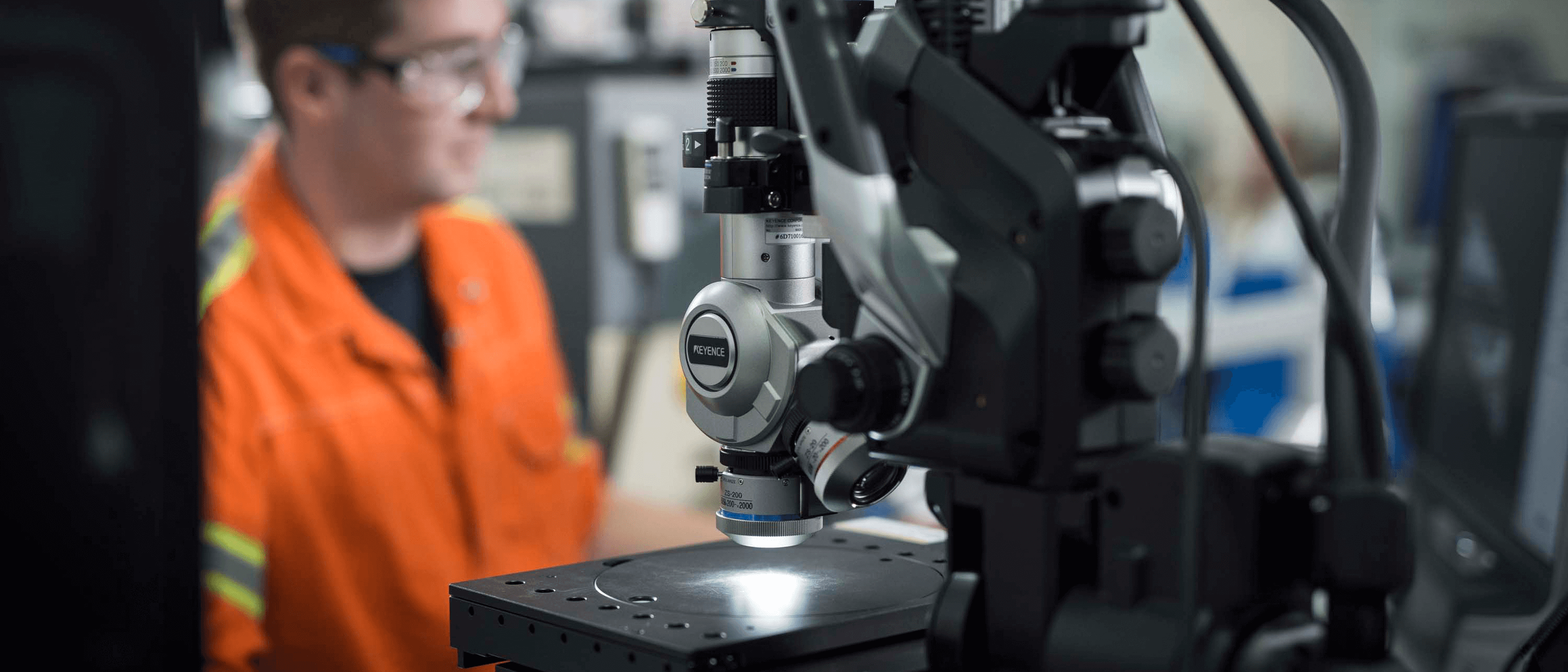

Testing in our own laboratory

Buderus Edelstahl has a testing laboratory at its production site in Wetzlar.

Modern testing equipment and image analysis systems, as well as experienced employees, ensure the

knowledge of the laboratory. The laboratory performs the classical material tests in the field of

metallic materials according to national and international standards such as:

Mechanical-technological test methods

- Tensile tests at test temperatures up to +600°C

- Notched bar impact tests up to 300 J, test temperatures from +300°C to -160°C

- Hardness tests (e.g. HB, HV, HRC)

- Determination of fracture mechanical properties (e.g. K1C, CTOD, J1C)

The “Deutsche Akkreditierungsstelle GmbH” (DAkkS) confirms the capability of testing laboratories with the certificate of competence according to DIN EN ISO/IEC 17025:2018

Metallography

- Manual and semi-automatic specimen preparation

- Automatic image analysis systems

- Microscopic cleanliness tests (e.g. DIN 50602, ISO 4967, ASTM E45)

- Microstructure, grain size investigations

- Damage examinations

Dilatometry

Non-destructive testing methods

- Ultrasonic immersion technique according to SEP 1927 on square and round specimens

Electron microscopy

- Scanning electron microscope with EDX and WDX analysis