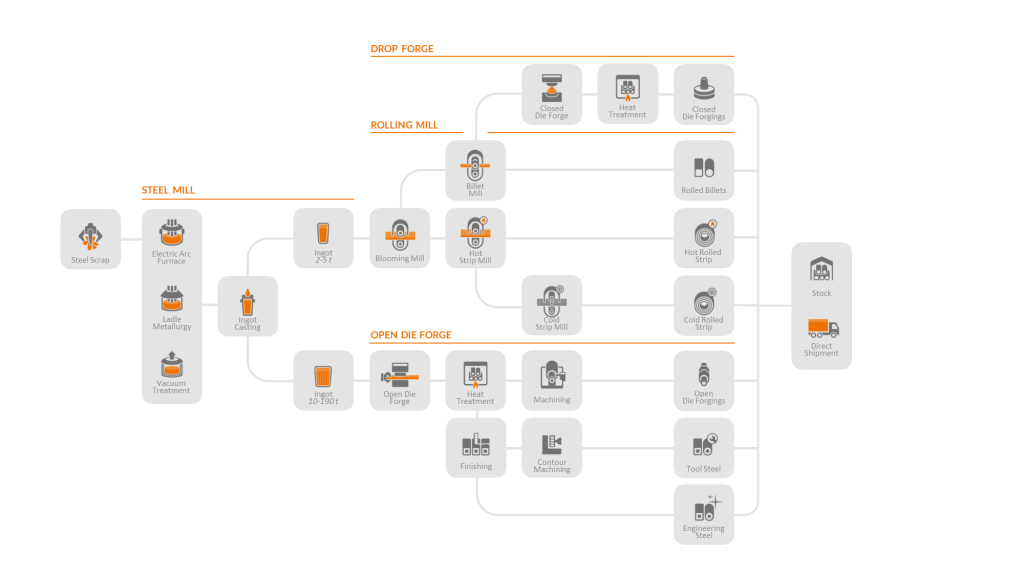

Our processes

Everything under control

With our large vertical range of manufacture, we retain control of the production process and thus of the quality of our products at all times. At the heart of our production is a 100-ton state-of-the-art electric arc furnace in which carefully pre-sorted steel scrap is melted to match the respective product. Our special steels are cast into ingot sizes from 2.8 to 190 tons. The large ingot stock as well as the finished stock for engineering and tool steel allow a quick response even to short-term requirements.

The ingots are processed into semi-finished products, hot strip or forged ingots and bar steel. We process our hot strip into high-quality cold-rolled strip in Wetzlar, supply semi-finished products to our drop forge where we manufacture ready-to-install components for the automotive and mechanical engineering industries, and machine our forged products mechanically to customer specifications.

Continuous improvement of product quality and manufacturing is one of our greatest strengths. Our certified quality assurance system specifies in detail all quality-relevant process steps and control points. Buderus Edelstahl’s own testing laboratory is approved by the “Deutsche Akkreditierungsstelle GmbH (DAkkS)”.