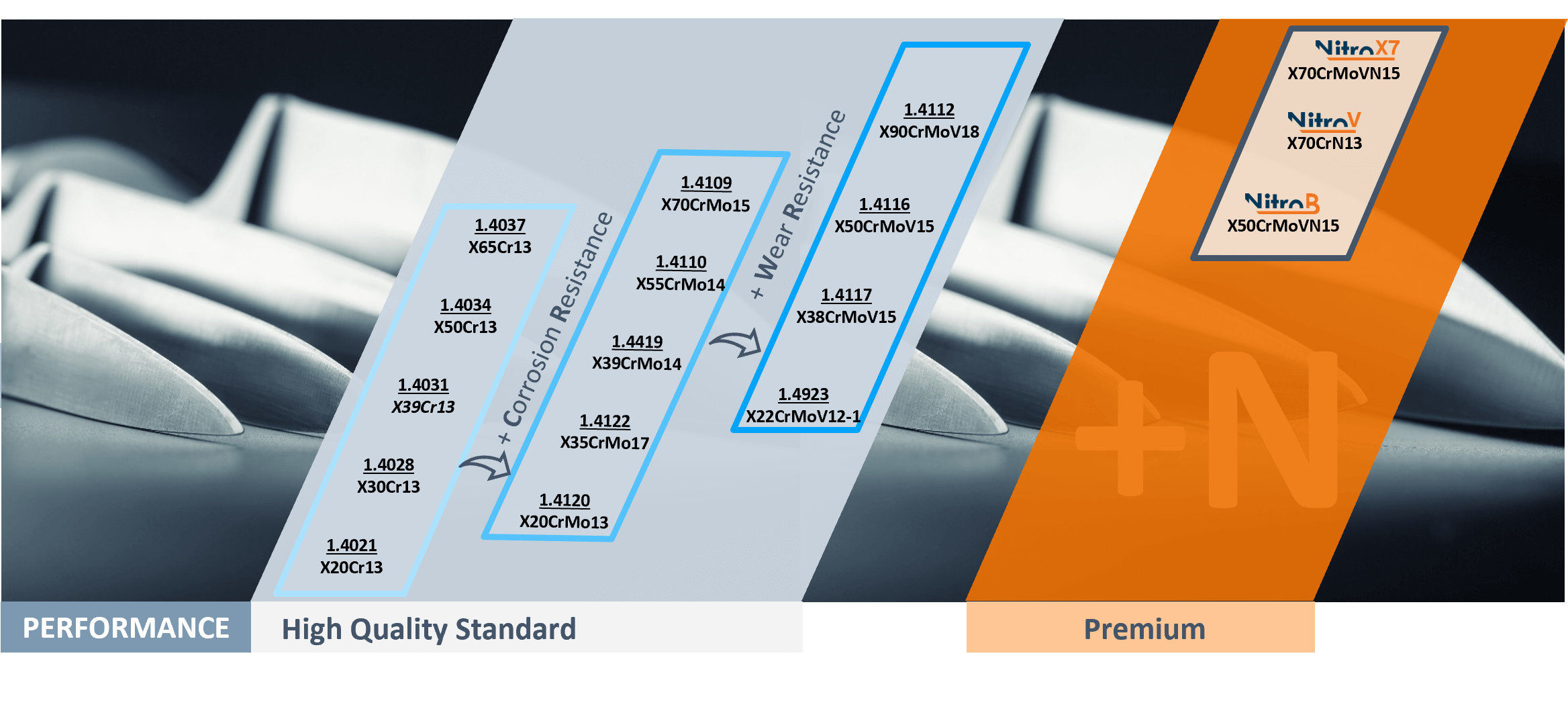

The concept of Nitro-x7

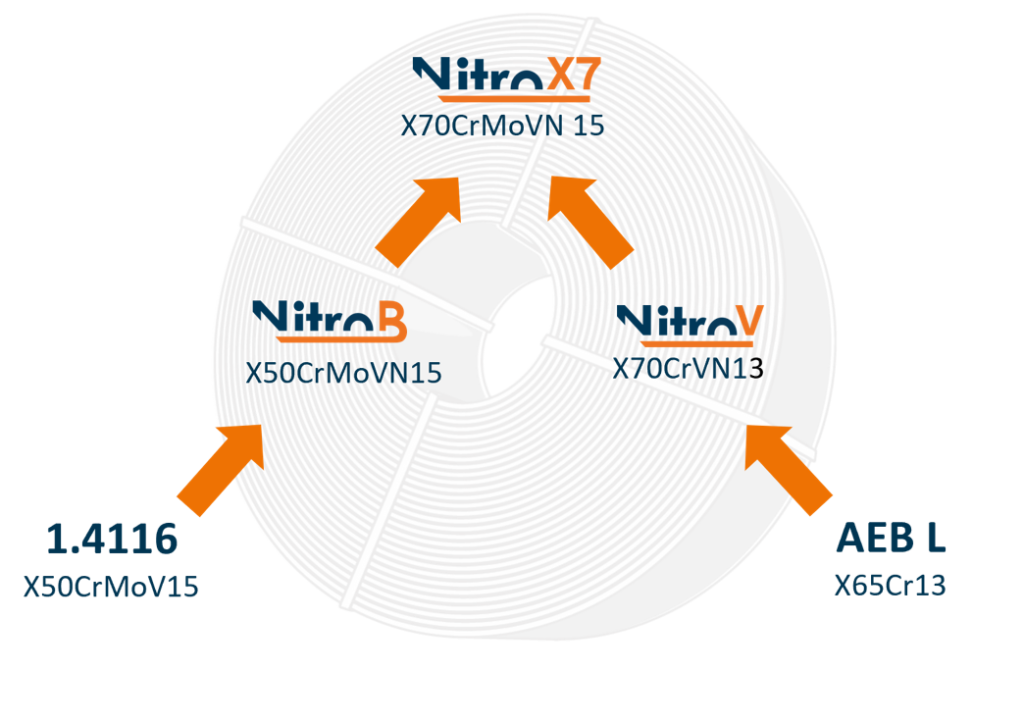

With the development of Nitro-X7, Buderus Edelstahl has succeeded in merging two development lines of stainless steels to create an exclusive high-tech knife steel. The combination of Nitro B and Nitro V raises the possibilities for conventionally melted knife steels to an unprecedented level.

The very high carbon content of Nitro V combined with the carbide- and nitride-forming elements of Nitro B give Nitro-X7 a very high density of the finest carbides and nitrides. This unprecedented variety of carbides and nitrides combined in a tough matrix forms the basis for the Nitro-X7.

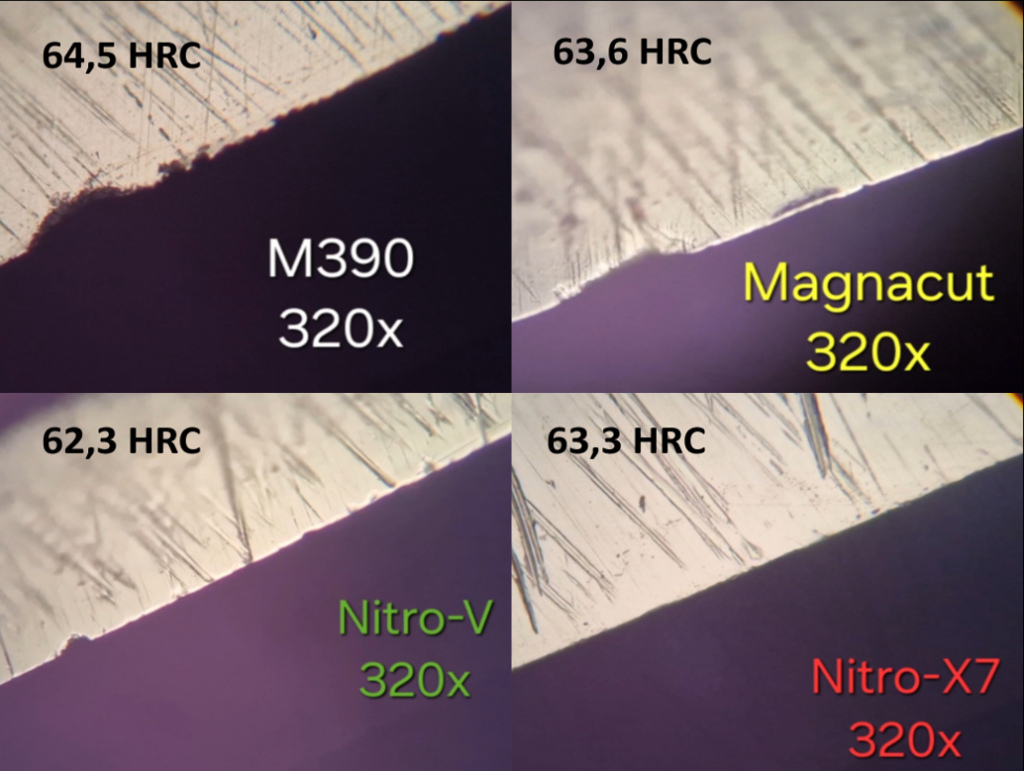

Initial tests with a knife tempered to 63.3 HRC show very good edge stability after cutting tests on staples, hardwood and roupe, which is on a par with conventional PM steels.

In terms of workability, the Nitro-X7 retains the well-known excellent properties of Buderus knife steels. This represents a direct advantage over PM steels.